Mitundu ya lamba wa mchenga woyenera kupukuta miyala ndi kupera

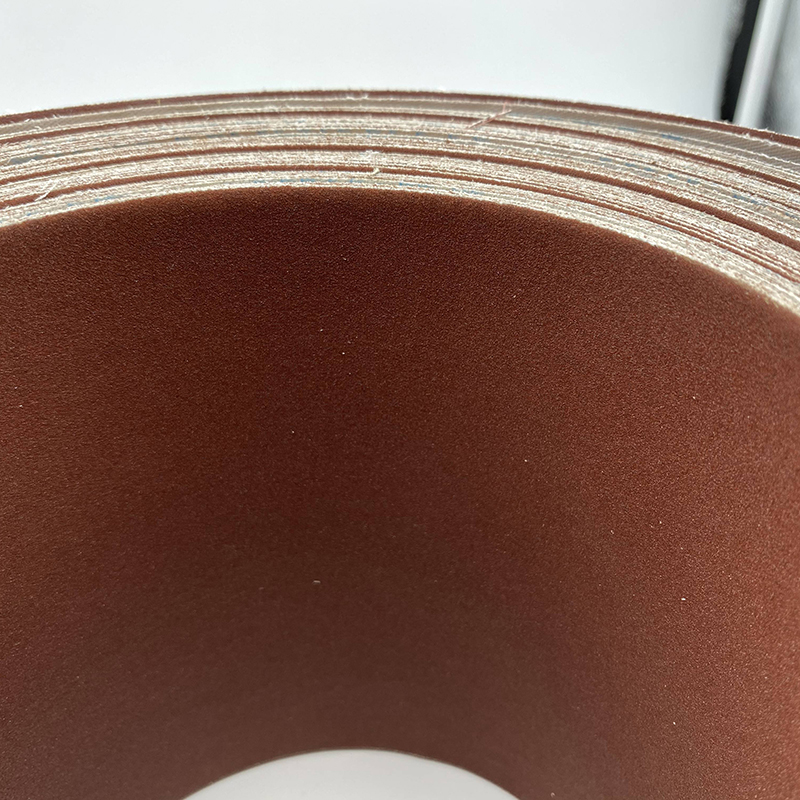

Brown wosakanizidwa aluminiyamu ndi corundum yokumba opangidwa ndi kusungunula ndi kuchepetsa zipangizo zitatu: bauxite, carbon material ndi filings chitsulo mu ng'anjo yamagetsi arc.Chigawo chachikulu cha mankhwala ndi AL2O3, zomwe zili 95.00% -97.00%, ndi Fe, Si, Ti, ndi zina.

Silicon carbide ndi chinthu chopangidwa ndi mankhwala a SiC.Amapangidwa ndi kutentha kwambiri kusungunuka kwa zinthu zopangira monga mchenga wa quartz, petroleum coke (kapena coke coke), ndi tchipisi tamatabwa (mchere umafunika kupanga green silicon carbide) kudzera mu ng'anjo yotsutsa.Pali mitundu iwiri yoyambira ya silicon carbide, yakuda silicon carbide ndi green silicon carbide, zonse zomwe ndi α-SiC.

Makhalidwe a miyala yosiyanasiyana

1. Marble amapangidwa pamaziko a miyala yamchere.Kumwamba kwake kumakhala ndi zokongoletsera zabwino pambuyo poyatsidwa ndi kupukutidwa.Komabe, zinthu zake ndizofewa kwambiri komanso zimakhudzidwa mosavuta ndi kusokoneza kwakunja.

2. Pamwamba pa miyala ya granite ndi yolimba ndipo ndi ya miyala ya volcanic, ndipo imakhala yabwino kwambiri kuti isavale komanso kuti isachite dzimbiri.Nthawi zambiri amagwiritsidwa ntchito pazitsulo zakhitchini kapena pansi.

3. Mwala wopangidwa ndi organic mulibe ma atomu a carbon mkati, kotero kuuma kwake kuli bwino kuposa mwala wopangidwa ndi organic.

4. Kuchulukana kwa mwala wopangidwa ndi organic ndikwambiri, sikungatenge madzi mosavuta, ndipo kumakhala ndi ntchito yabwino yosindikiza, ndipo kuchuluka kwa exfoliation ndikwabwino kuposa mwala wopangidwa ndi inorganic.Komabe, mawonekedwe ake ndi ofanana ndi pulasitiki ndipo amakhudzidwa ndi kuwonjezereka kwa kutentha ndi kuchepetsedwa.

Zomwe zili m'munsi mwa lamba wa abrasive ziyenera kukhala ndi mphamvu zinazake komanso kutalika kochepa.

Mphamvu ya zinthu zoyambira ndizogwirizana kwambiri ndi mphamvu ya lamba wa abrasive.Pokhapokha ndi mphamvu zambiri, lamba wa abrasive amatha kupirira kukhudzidwa kwa katundu wovuta, kusinthana katundu, kugaya katundu ndi katundu wowonjezera panthawi yopera.

Elongation ndi chizindikiro chofunikira kwambiri cha zinthu zoyambira.Ngati lamba abrasive amafikira kwambiri pansi pa zochita za kunja mphamvu, ndi abrasive particles adzagwa ndi kutaya mphamvu akupera.Kuwonjeza mochulukira kudzaposa kuchuluka kosinthika kwa lamba wa abrasive wa chopukusira.Zotsatira zake, lamba wa abrasive sungagwiritsidwe ntchito.

Njira Yopukutira

1. Contact gudumu mtundu

Lamba wa abrasive akupera polumikizana ndi workpiece ndi gudumu lolumikizana.Ikhoza kugwiritsidwa ntchito pokonza bwalo lakunja, dzenje lamkati ndi ndege ya workpiece, ndipo gudumu lolumikizana likhoza kupangidwa kukhala mawonekedwe enaake kuti apange malo opindika a workpiece.Kupera ndi mawilo oyandama kukhudzana angagwiritsidwenso ntchito limodzi ndi processing wa mbiri osakhazikika.

2. Mtundu wa mbale yopera

Pakupera, lamba wa abrasive amalumikizana ndi chogwirira ntchito kudzera mu mbale yopumira.Mbalame yopopera mphamvu imakhala ndi mphamvu yopondereza ndipo imagwiritsidwa ntchito pokonza ndege, yomwe imatha kuonjezera malo okhudzidwa, kupititsa patsogolo kugaya bwino komanso kulondola kwa geometric kwa workpiece, makamaka flatness.

3. Freestyle

Chogwiritsiridwa ntchito chimagwirizana mwachindunji ndi lamba wosinthika wa abrasive popanda chinthu chilichonse chothandizira lamba wotsekemera.Imagwiritsa ntchito kusinthasintha kwake pambuyo poti lamba wakhazikika kuti akupera kapena kupukuta chogwirira ntchito.Njira imeneyi n'zosavuta kuti azolowere mdulidwe wa workpiece mkati osiyanasiyana, makamaka mawonekedwe osasamba workpiece, ndipo makamaka ntchito pokonza akunja akamaumba pamwamba ndi chamfering, deburring, kupukuta ndi njira zina.